A Winkelbohrspindel is a specialized mechanical component used in machining processes where drilling, milling, or tapping must be performed at an angle rather than along the main spindle axis. The word itself comes from German engineering terminology, where “Winkel” means angle and “Bohrspindel” means drilling spindle. As the name suggests, this unit allows the transmission of rotational motion through a defined angle, most commonly 90 degrees, enabling machining operations in locations that are otherwise inaccessible with a straight spindle.

In modern manufacturing, compact designs, complex geometries, and high productivity demands have made the Winkelbohrspindel an essential tool across industries such as automotive, aerospace, general machinery, and automated production systems. This article explains what a Winkelbohrspindel is, how it works, where it is used, and what technical and operational factors define its performance.

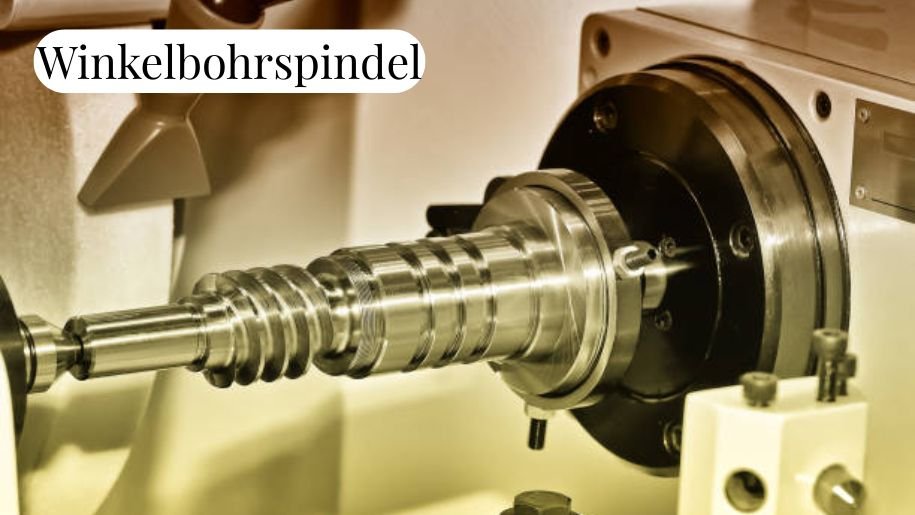

Fundamental Purpose of a Winkelbohrspindel

The primary purpose of a Winkelbohrspindel is to redirect rotational motion from the machine’s main drive into a different orientation. Traditional drilling or milling spindles operate along a straight axis, which can limit accessibility when components have deep cavities, side walls, or obstructed surfaces.

A Winkelbohrspindel solves this limitation by enabling machining at an angle without repositioning the workpiece. This not only improves machining flexibility but also significantly reduces setup time, increases accuracy, and enhances overall production efficiency.

Basic Construction and Design Principles

At its core, a Winkelbohrspindel consists of a robust housing that contains a set of precision gears and bearings. These internal components transmit torque from the input shaft to the output shaft while changing the direction of rotation.

The housing is usually made from hardened steel or high-strength alloys to withstand mechanical stress and vibration. Inside the housing, the gear system is the heart of the spindle. Depending on design requirements, bevel gears, spiral bevel gears, or planetary gear arrangements are used. These gears must be precisely machined to ensure smooth power transmission, minimal backlash, and long service life.

High-precision bearings support both the input and output shafts. These bearings are responsible for maintaining concentricity, minimizing runout, and absorbing radial and axial loads generated during cutting operations. Sealing systems protect the internal components from chips, coolant, and contaminants, which is critical for reliable long-term operation.

Working Principle of a Winkelbohrspindel

The working principle of a Winkelbohrspindel is relatively straightforward but requires high mechanical precision. When the machine spindle rotates, its motion is transferred to the input shaft of the Winkelbohrspindel. This rotation enters the internal gear system, which redirects the rotational axis by a predetermined angle.

The redirected rotation exits through the output shaft, where the cutting tool is mounted. Despite the change in direction, the spindle must maintain consistent speed, torque, and accuracy. Any deviation can lead to tool wear, vibration, or poor surface finish.

Advanced designs ensure that power losses are minimal and that torque delivery remains stable even at high speeds. This is particularly important in high-speed drilling or fine milling applications where precision is critical.

Types of Winkelbohrspindel

Winkelbohrspindeln are available in various configurations to suit different machining needs. Some are designed as passive units driven by the machine spindle, while others include integrated motor systems. Passive Winkelbohrspindeln rely entirely on the machine’s main drive, making them simpler and lighter. Motorized versions, on the other hand, offer greater control over speed and torque and are often used in complex or high-precision applications.

Another important distinction lies in fixed-angle versus adjustable-angle spindles. Fixed-angle units, typically set at 90 degrees, are the most common due to their rigidity and reliability. Adjustable-angle designs provide flexibility but are mechanically more complex and usually reserved for specialized tasks.

Materials and Manufacturing Quality

The performance of a Winkelbohrspindel is closely tied to the quality of its materials and manufacturing processes. High-grade steels with excellent fatigue resistance are used for shafts and gears. Heat treatment processes such as carburizing or nitriding are applied to improve surface hardness while maintaining a tough core.

Precision grinding ensures tight tolerances and smooth gear meshing. Even minor inaccuracies can lead to noise, vibration, and premature wear. As a result, high-quality Winkelbohrspindeln are often produced using advanced CNC grinding and inspection technologies.

Accuracy, Runout, and Performance Characteristics

Accuracy is a defining factor for any machining spindle, and the Winkelbohrspindel is no exception. Runout values must be kept extremely low to ensure precise hole positioning and consistent surface finishes. High-performance models achieve runout values measured in microns, making them suitable for precision engineering tasks.

Torque capacity is another critical characteristic. Depending on the application, a Winkelbohrspindel may be required to deliver high torque at low speeds or moderate torque at very high speeds. The gear ratio inside the spindle determines this balance and must be selected according to the machining task.

Thermal stability also plays a role. During continuous operation, heat buildup can affect tolerances. Well-designed spindles incorporate efficient lubrication and cooling strategies to maintain dimensional stability.

Applications in Modern Manufacturing

Winkelbohrspindeln are widely used wherever angled machining is required. In the automotive industry, they are essential for drilling and tapping engine blocks, transmission housings, and structural components. Aerospace manufacturers rely on them for machining complex aluminum and titanium parts with restricted access.

In automated production lines, Winkelbohrspindeln are often integrated into transfer machines and special-purpose equipment. Their ability to perform side drilling operations without repositioning the workpiece makes them invaluable in high-volume manufacturing.

They are also commonly used in mold and die making, where intricate geometries demand flexible machining solutions.

Integration with CNC and Automation Systems

Modern Winkelbohrspindeln are designed to integrate seamlessly with CNC machines and automated systems. Mounting interfaces are standardized to allow quick installation and alignment. In CNC environments, tool offsets and spindle orientation must be carefully programmed to ensure accurate machining.

Motorized Winkelbohrspindeln can be synchronized with machine controls, allowing variable speed adjustment and real-time monitoring. This level of integration supports advanced manufacturing strategies such as multi-axis machining and automated tool changes.

Maintenance and Service Life

Proper maintenance is essential for maximizing the lifespan of a Winkelbohrspindel. Regular inspection of bearings, gears, and seals helps prevent unexpected failures. Lubrication plays a crucial role, as inadequate lubrication can lead to overheating and accelerated wear.

High-quality spindles are designed for long service intervals, but operating conditions such as cutting forces, speed, and coolant exposure directly affect longevity. Preventive maintenance strategies significantly reduce downtime and ensure consistent performance.

Advantages of Using a Winkelbohrspindel

One of the greatest advantages of a Winkelbohrspindel is its ability to reduce machine setups. By enabling angled machining in a single setup, it improves accuracy and shortens production cycles. It also expands the capabilities of existing machines, eliminating the need for additional equipment.

From a productivity standpoint, Winkelbohrspindeln contribute to higher output, better surface quality, and improved process reliability.

Limitations and Engineering Considerations

Despite their advantages, Winkelbohrspindeln are not without limitations. The redirection of power introduces mechanical complexity, which can result in higher costs compared to standard spindles. Power losses, although minimal in high-quality designs, are still greater than in direct-drive systems.

Engineers must carefully consider load limits, speed ranges, and space constraints when selecting a Winkelbohrspindel. Improper selection can lead to inefficiency or premature failure.

Future Developments and Trends

As manufacturing continues to evolve, Winkelbohrspindeln are becoming more compact, efficient, and intelligent. Advances in materials, bearing technology, and digital monitoring are improving performance and reliability. Integration with smart manufacturing systems allows predictive maintenance and real-time performance analysis.

The demand for flexible, high-precision machining solutions ensures that Winkelbohrspindeln will remain a key component in modern production environments.

Frequently Asked Questions (FAQs)

What is the main function of a Winkelbohrspindel?

Its main function is to enable drilling, milling, or tapping at an angle by redirecting rotational motion from the main spindle.

Is a Winkelbohrspindel always set at 90 degrees?

Most are designed for 90-degree operation, but adjustable and custom angle versions also exist for specialized applications.

Can a Winkelbohrspindel be used on CNC machines?

Yes, many Winkelbohrspindeln are specifically designed for CNC integration and automated machining systems.

How accurate is a Winkelbohrspindel compared to a standard spindle?

High-quality Winkelbohrspindeln can achieve extremely low runout and precision comparable to standard spindles.

What factors affect the lifespan of a Winkelbohrspindel?

Operating speed, load, lubrication quality, maintenance practices, and environmental conditions all influence service life.